The world of 3D printing has brought about incredible advancements in manufacturing and design, allowing for the creation of three-dimensional objects from digital files. As this technology continues to evolve and become more accessible, many individuals and businesses are considering investing in a 3D printer. However, one crucial aspect that often comes into play is the 3d printer machine price.

Understanding 3D Printers

Before delving into the various price ranges, it’s essential to grasp the fundamentals of 3D printers. These remarkable devices work by building objects layer by layer, using materials such as plastics, resins, or metals. They rely on computer-aided design (CAD) files to precisely replicate the desired item.

Types of 3D Printers

When it comes to 3D printers, there are several types available in the market. The most common ones include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP). Each type utilizes different techniques and materials, catering to specific applications and industries.

Factors Affecting 3d printer machine price

Several factors influence the 3d printer machine price. One of the primary considerations is the quality and precision of the print output. Higher-end machines with superior accuracy and finer details tend to come at a higher cost. Printing speed and build volume also contribute to pricing, as faster machines with larger build volumes generally command a higher price tag. Additionally, the compatibility with a wide range of materials and the inclusion of advanced features and automation can further increase the cost of a 3D printer.

Entry-Level 3d printer machine price

For beginners or hobbyists looking to explore the world of 3D printing, entry-level printers offer an affordable starting point. These machines typically come at a price range of $200 to $500. While they may not possess all the advanced features of higher-end models, they still provide adequate functionality for basic printing needs.

Mid-Range 3d printer machine price

Mid-range 3D printers offer a balance between affordability and enhanced features. With prices ranging from $500 to $2,000, these printers cater to small businesses and educational institutions seeking a higher level of print quality and versatility. They often come with larger build volumes, faster printing speeds, and improved material compatibility.

High-End 3d printer machine price

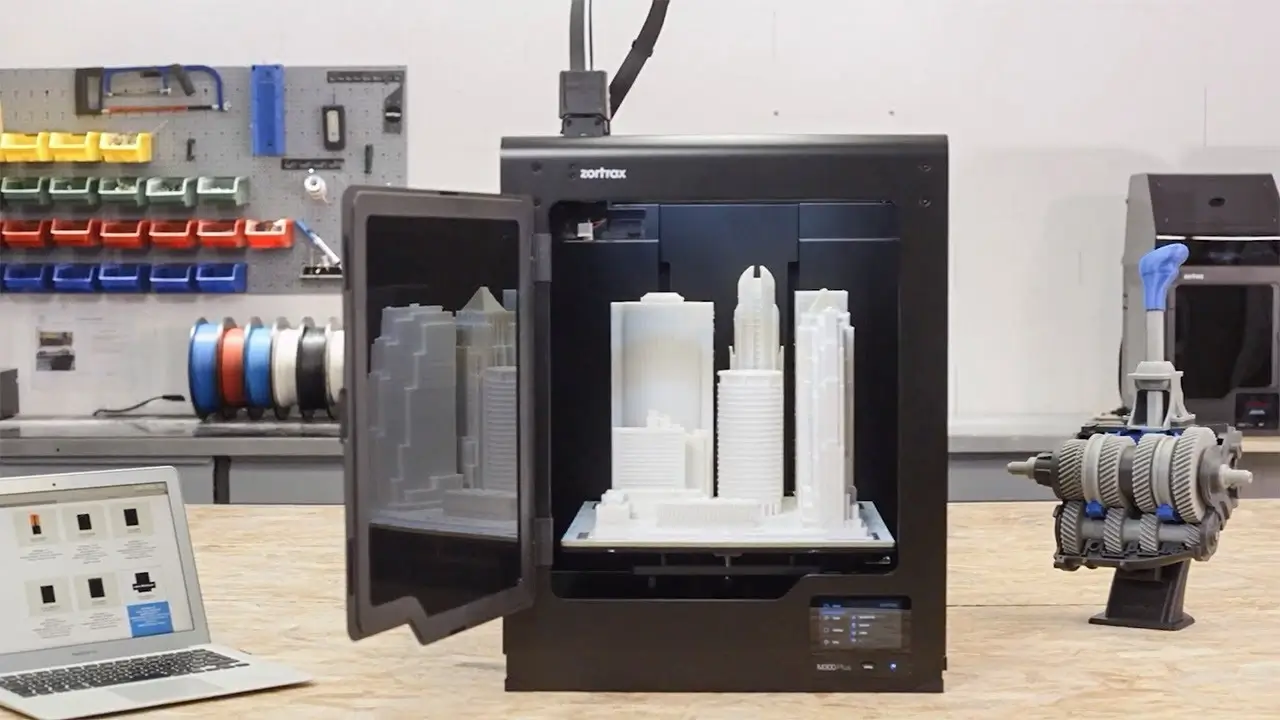

At the top end of the spectrum, high-end 3D printers offer exceptional performance and capabilities. These professional-grade machines can range from $2,000 to well over $10,000. They are designed for industrial applications and meet the demands of professionals requiring superior print quality, precision, and reliability. These high-end printers often incorporate advanced features such as dual extruders, larger build volumes, and compatibility with a wide range of materials.

Also check: Best Things To 3d Print And Sell

Factors to Consider when Buying a 3D Printer

When contemplating the purchase of a 3D printer, several factors should be taken into account. First and foremost, it is crucial to identify specific needs and requirements. Consider the intended use of the printer, the level of print quality desired, and the types of materials you plan to work with. Additionally, evaluating the long-term cost-effectiveness and return on investment is essential, including factors such as the cost of consumables, maintenance, and potential upgrades. Compatibility with software and the availability of technical support and community resources are also important considerations.

Popular 3D Printer Brands and Models

Regarding 3D printers, several reputable brands offer reliable and high-quality machines. Let’s take a look at some of the famous brands and their notable models:

-

- Ultimaker: Ultimaker is renowned for producing professional-grade 3D printers that deliver exceptional print quality and reliability. Their models, such as the Ultimaker S5 and Ultimaker 3, are equipped with advanced features like dual extruders and large build volumes, making them suitable for various applications.

- MakerBot: MakerBot is a well-established brand in the 3D printing industry, known for its user-friendly and accessible printers. The MakerBot Replicator+ and MakerBot Method series are popular among educators, designers, and small businesses due to their ease of use, reliable performance, and versatile printing capabilities.

- Prusa Research: Prusa Research has gained a strong following for its open-source 3D printers, which offer excellent value for money. The Prusa i3 MK3S+ and Prusa Mini+ are highly regarded for their affordability, reliability, and continuous firmware and software updates, which provide users with an optimal printing experience.

- Formlabs: Formlabs specializes in producing high-resolution stereolithography (SLA) printers widely used in engineering, jewelry, and healthcare industries. The Formlabs Form 3 and Formlabs Form 3L offer impressive print quality and precision, making them suitable for detailed and intricate designs.

- Creality: Creality has gained popularity for its cost-effective 3D printers that cater to beginners and enthusiasts. The Creality Ender 3 and Creality CR-10 series have become favorites among hobbyists thanks to their affordability, ease of use, and the ability to produce decent print quality.

What is the difference between a 3D printer and a 3D scanner?

Cost of Consumables and Maintenance

When considering the purchase of a 3D printer, it’s important to factor in not only the initial cost of the machine but also the ongoing expenses for consumables and maintenance. Let’s take a closer look at these aspects:

Overview of Consumables:

The most common consumables used in 3D printing are filaments, resins, and powders. Filaments are primarily used in Fused Deposition Modeling (FDM) printers, while resins are used in Stereolithography (SLA) and Digital Light Processing (DLP) printers. Powders are utilized in Selective Laser Sintering (SLS) printers. These consumables come in various materials such as PLA, ABS, PETG, resin-based polymers, and metal powders.

Examining Ongoing Expenses for Materials:

The cost of consumables can vary depending on the material, quality, and brand. Filaments for FDM printers typically range from $20 to $50 per kilogram, depending on the type and quality. Resins for SLA and DLP printers can range from $30 to $150 per liter. Metal powders for SLS printers are generally more expensive, ranging from $100 to $500 per kilogram.

The consumption rate of these materials depends on the complexity and size of the printed objects. Larger and more intricate prints require more material, leading to increased costs. It’s essential to consider the estimated material consumption for your intended projects and calculate the ongoing expenses accordingly.

Maintenance Requirements and Associated Costs:

Like any other piece of machinery, 3D printers require regular maintenance to ensure optimal performance and longevity. Maintenance tasks may include cleaning the print bed, replacing or cleaning the nozzle, calibrating the printer, and updating firmware and software.

The frequency and complexity of maintenance tasks vary depending on the printer model and usage. It’s advisable to follow the manufacturer’s guidelines and recommendations for maintenance procedures. Some maintenance tasks can be performed by the user, while others may require professional assistance.

Associated costs for maintenance include replacement parts, such as nozzles and belts, which can range from a few dollars to tens of dollars. Additionally, if professional assistance is needed for maintenance or repairs, there may be service charges or labor costs involved.

Calculating the Total Cost of Ownership:

To accurately assess the cost of owning a 3D printer, it’s important to calculate the total cost of ownership (TCO). The TCO includes the initial purchase price of the printer, ongoing expenses for consumables, and maintenance costs over a specific period.

By considering the estimated material consumption, maintenance requirements, and associated costs, you can calculate the TCO for your 3D printer. This will help you budget and determine the feasibility of owning a 3D printer for your intended projects or business.

Remember to factor in the lifespan of the printer, as well as any potential upgrades or additional accessories that may be required in the future. Understanding the TCO allows you to make an informed decision and plan accordingly for the overall cost of operating a 3D printer.

Explore: e plus sls 3d printer

Future of 3D Printing

As 3D printing technology continues to evolve at a rapid pace, the future holds exciting advancements and innovations that will shape various industries. Here are some predictions and insights into the future of 3D printing:

Predicting Advancements and Innovations:

The future of 3D printing is expected to bring significant advancements in several areas. One key area is improving print speed and efficiency. Researchers and engineers continuously work on enhancing the printing process to reduce printing times while maintaining high print quality.

Additionally, there will likely be advancements in materials used for 3D printing. This includes developing new materials with enhanced strength, flexibility, and conductivity properties. Moreover, combining multiple materials in a single print, known as multi-material 3D printing, is poised to become more accessible and widely used.

Furthermore, the field of bioprinting holds great promise for the future. Scientists are exploring the ability to print functional human organs, tissues, and implants, which could revolutionize healthcare and organ transplantation.

Potential Impact on Various Industries:

The impact of 3D printing on various industries is already significant, and it is expected to grow even further in the future. Industries such as manufacturing, aerospace, automotive, healthcare, architecture, and consumer goods embrace 3D printing technology to streamline production, reduce costs, and enable greater customization.

In manufacturing, 3D printing allows for rapid prototyping, on-demand production, and decentralized manufacturing. This can lead to shorter product development cycles and reduced waste.

The aerospace and automotive industries benefit from 3D printing by creating lightweight components with complex geometries, enhancing fuel efficiency, and reducing assembly requirements.

In the healthcare sector, 3D printing enables the creation of personalized medical devices, prosthetics, and implants tailored to individual patients’ needs. This technology has the potential to revolutionize patient care and improve treatment outcomes.

Read more: Disadvantages of 3D Printing in Pharmaceutical Industry

Accessibility and Affordability in the Future:

As 3D printing technology matures and becomes more widespread, it is expected to become increasingly accessible and affordable. The cost of 3D printers has already significantly reduced over the years, making them more attainable for individuals, small businesses, and educational institutions.

Moreover, advancements in open-source hardware and software have fostered a vibrant maker community, promoting collaboration, knowledge sharing, and the democratization of 3D printing technology. This open approach has the potential to drive innovation and bring down costs even further.

The Role of 3D Printing in Sustainability:

3D printing has the potential to contribute to sustainability efforts in several ways. By enabling on-demand production and localized manufacturing, it can reduce transportation-related carbon emissions and decrease waste associated with mass production and excess inventory.

Furthermore, 3D printing allows for the use of recycled or biodegradable materials, reducing reliance on traditional manufacturing methods that generate significant waste. The ability to print intricate and optimized designs can also result in material savings.

In sectors such as architecture and construction, 3D printing can revolutionize building practices by using sustainable and locally sourced materials, reducing energy consumption, and minimizing construction waste.

Best 3D Printers for Beginners

Conclusion

In conclusion, the future of 3D printing looks promising with advancements in speed, materials, and bioprinting. The technology will continue to impact various industries, enabling customization, reducing costs, and improving efficiency. As 3D printing becomes more accessible and affordable, it will unlock new opportunities for individuals and businesses alike. Embracing 3D printing and staying informed about its potential will be crucial in harnessing its benefits and exploring the possibilities it offers.

FAQs

What is the average price of an entry-level 3D printer?

The average price of an entry-level 3D printer typically ranges from $200 to $500. However, it's important to note that prices can vary depending on factors such as brand, features, and build volume.

Are expensive 3D printers always better in terms of print quality?

While expensive 3D printers often come with advanced features and higher build quality, it doesn't necessarily mean they always offer better print quality. Factors such as proper calibration, print settings, and material selection also play a crucial role in achieving high-quality prints. It's important to research and compare reviews of different models to find the best printer for your specific requirements

Can I use any material with a 3D printer?

The compatibility of materials depends on the type of 3D printer you have. Each printer is designed to work with specific materials. For example, Fused Deposition Modeling (FDM) printers use thermoplastic filaments, while Stereolithography (SLA) and Digital Light Processing (DLP) printers use liquid resins. It's essential to check the manufacturer's specifications and recommendations to determine the compatible materials for your 3D printer.

What maintenance tasks are required for a 3D printer?

Maintenance tasks for a 3D printer may include cleaning the print bed, unclogging or replacing the nozzle, lubricating moving parts, and leveling the print bed. Regular cleaning and calibration are necessary to ensure optimal print quality and prevent issues. It's recommended to consult the user manual or manufacturer's guidelines for specific maintenance instructions tailored to your printer model.

How can 3D printing contribute to the medical field?

3D printing has significant potential in the medical field. It enables the production of customized medical devices, prosthetics, implants, and anatomical models. Surgeons can use 3D-printed models for preoperative planning and practice complex procedures. Bioprinting, which involves printing living cells, has the potential to revolutionize tissue engineering and organ transplantation. Additionally, 3D printing can facilitate the production of personalized drug delivery systems and assistive devices for individuals with disabilities.

Remember, the answers provided are general guidelines, and it’s always advisable to consult specific product information, user manuals, or seek expert advice when dealing with individual 3D printers and their respective functionalities.