Endureal 3D printer

Jigs & Fixtures For Manufacturing Lines, Large end-use parts, Chemical-resistant models, Functional aerospace & automotive prototypes, Support tools for machines, Functional space parts.

Jigs & Fixtures For Manufacturing Lines, Large end-use parts, Chemical-resistant models, Functional aerospace & automotive prototypes, Support tools for machines, Functional space parts.

Dual & Single

200-250 microns

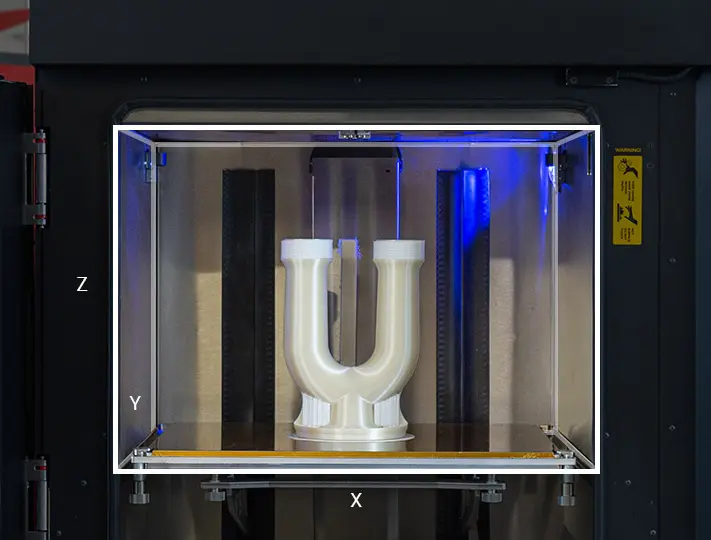

400 x 300 x 300 mm, 15.7 x 11.8 x 11.8 in

Job-specific printing modules and developed printing profiles

A chemicaly resistant T-junction pipe 3d printed with Z-PEEK and Saluble Z-SUPPORT ATP 130

Triple clamp 3D printed with BASF Ultrafuse® 17-4 PH before the debinding and sintering procedures

Bevel gear 3D printed with BASF Ultrafuse® 316L after the debinding and sintering procedures

Abrasion-resistant gears 3D printed with Z-PEEK

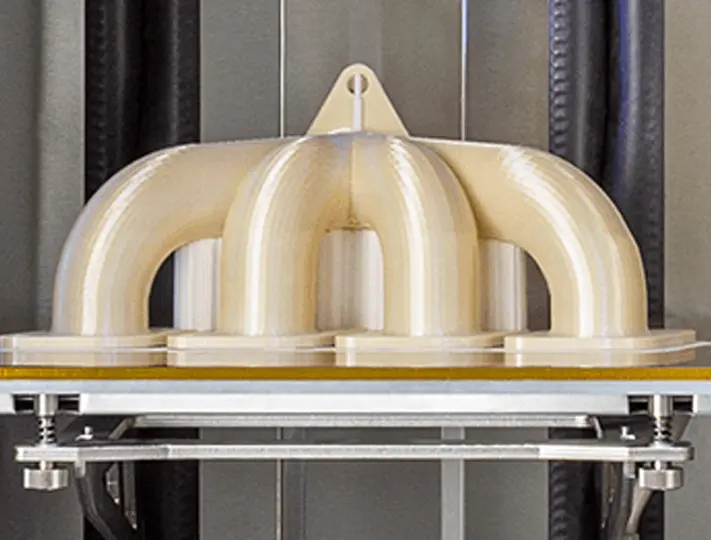

A turbo air intake manifold printed with Z-PEI 9085

Temperature resistant thermostat housing 3D printed with Z-PEI 1010

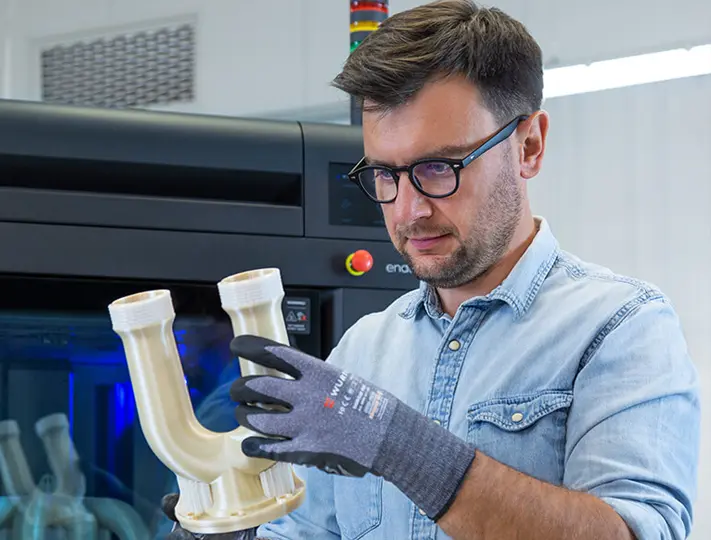

Being a full-fledged industrial machine, Endureal is as fast to set up and easy to operate as Zortrax desktop-class 3D printers. Intuitive user interface and software with carefully tuned settings predefined for each dedicated filament make Endureal ready to work at full capacity from day one.

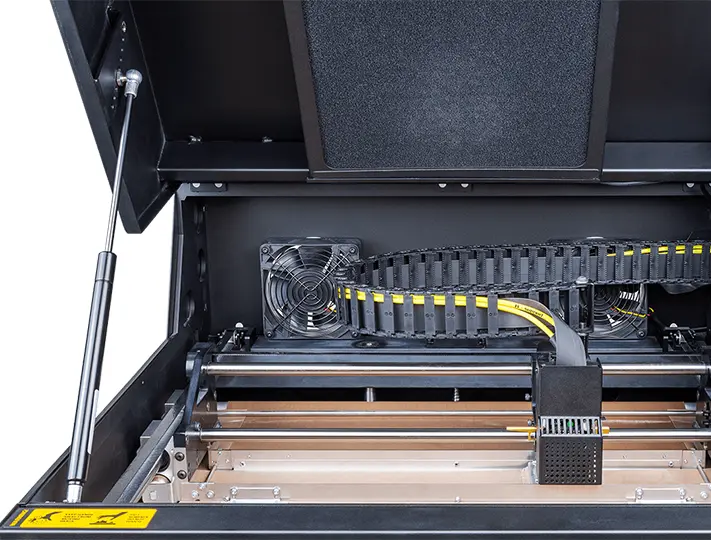

Endureal has an enclosed prinitng chamber designed for the most challenging materials like Z-PEI 9085, Z-PEI 1010, or different blends of PEEK. It can be heated up to 200 °C. Such high temperatures are necessary to minimize shrinkage in large-format prints

The Endureal has been designed to work with a range of hightemp polymers. Z-PEI 9085, Z-PEI 1010, and blends of PEEK are all industrial materials with strength-to weigth ratio comparable to metal alloys. Due to their uniqe properties, such materials are used in high tech fields like aviation and space industry.

A build platform in the Endureal is made of aluminum covered with PEI film to ensur proper adhesion for all supported filaments. The platform is designed to withstand tempratures reaching 220 °C which are necessary to efficeintly print high-performance polymers.

Endureal’s operation is monitored in real time by a wide array from sensors. Everything from air humidity in the filament’s compartment, to tempratures in its critical modules is tightly controlled. The printer can detect multiple issues like over heating or filament shortages and notify the User.

In emergencies, its operation can be immediatley stopped by hitting a clearly visible safe button.

The printers can simultaneously work with two filaments, one for the model, and the other one for soluble or breakaway support structures. This makes it capable of fabricating models with complex internal geometries, movable mechanisms, and other shapes that would have been impossible to print in a single-extrusion mode.

| Device | Specifications |

|---|---|

| Build volume | 400 x 300 x 300 mm (15.7 x 11.8 x 11.8 in) |

| Nozzle Diameter | 0.4 mm (0.016 in) |

| Extruder | Dual material |

| Extruder cooling system | Two fans cooling the extruder, radial fan cooling the print |

| Hotend | High-temperature dual hotend |

| Platform | Heated; aluminum plate coated with PEI |

| Material Sensors | 2 x mechanical endstop, 2 x material weight sensor |

| Connectivity | Wi-Fi, Ethernet, USB |

| Operating System | Android |

| Processor | Quad Core |

| Touchscreen | 7” IPS 1024 x 600 |

| Camera | Yes |

| Filaments | Specifications |

|---|---|

| Dedicated for single extrusion | Z-ABS, Z-ULTRAT, Z-PEI 9085, BASF Ultrafuse® ABS, BASF Ultrafuse® PPSU, BASF Ultrafuse® PC/ABS FR, Nanovia PC-ABS V0 |

| Dedicated for dual extrusion | Z-ABS, Z-PEEK, Z-PEI 1010, Z-PEI 9085, Z-SUPPORT ATP, Z-SUPPORT ATP 130, Z-SUPPORT High-Temp, Z-ULTRAT, BASF Ultrafuse® 17-4 PH, BASF Ultrafuse® 316L, BASF Ultrafuse® Support Layer, BASF Ultrafuse® ABS, BASF Ultrafuse® PC/ABS FR, VICTREX AM™ 200 FIL, Nanovia PC-ABS V0 |

| External Materials | Applicable |

| Support | Mechanically removed – printed with the same material as the model Break-away – printed with a different material than the model Soluble – printed with a different material than the model |

| Filament Container | Spool |

| Filament Diameter | 1.75 mm (0.069 in) |

| Printing | Specifications |

|---|---|

| Technology | LPD Plus (Layer Plastic Deposition Plus) – advanced technology depositing melted thermoplastics with break-away and dissolvable support structures |

| Layer resolution | 200-250 microns |

| Minimal wall thickness | 450 microns |

| platform Leveling | Automatic measurement of platform points’ height |

| Temprature | Specifications |

|---|---|

| Maximum Printing Temprature (Extruder) | 480 °C (896 °F) |

| Maximum Platform Temprature | 220 °C (428 °F) |

| Maximum Build Champer Temprature | 200 °C (392 °F) |

| Ambient Operation Temprature | 17-30 °C (63-86 °F) |

| Storage Temprature | 0-35 °C (32-95 °F) |

| Electrical | Specifications |

|---|---|

| Ac Input | 120 V ~ 13 A 50/60 Hz

200 - 240 V ~ 9.5 A 50/60 Hz |

| Maximum Power Consumption | 120 V - 1600 W

200 - 240 V - 2300 W |

| Software | Specifications |

|---|---|

| Software Bundle | Z-SUITE |

| Support Input File Types | .stl, obj, .dxf, .3mf, .ply |

| Supported Operating System | Mac OS Catalina and newer versions / Windows 10 and newer versions |

Please fill out the form to request a quote. We will get back to you within 24 hours of receiving your request. Thank you for your patience

All Rights Reserved | 2B DIGITAL © 2025

جميع الحقوق محفوظة | 2B Digital © 2025

صمم بواسطة Thinkadv