Industry: Construction Robotics · Autonomous Systems · Smart Infrastructure

Technology: Cloud-Based MODSIM · 3D CAD · Data Collaboration

Application: Smart robot design · Simulation-driven development · Cross-functional collaboration

Overview: Building Award-Winning Robotics in Just 2.5 Months

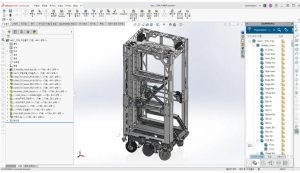

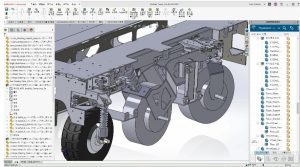

GOLE Robotics, a South Korean startup, developed its first autonomous construction robot module in only two and a half months using SOLIDWORKS and 3DEXPERIENCE® Works solutions. The robot went on to win a CES 2024 Innovation Award. Through seamless integration between hardware, software, and electrical teams on the cloud, GOLE cut development costs by 10% and reduced the robot’s weight by 20%.

The Challenge: Rapidly Build a Smart Robot for Construction Sites

Fast Time to Market – The team needed to design, validate, and manufacture in record time

Cross-Team Collaboration – Required full alignment between mechanical, software, and electrical disciplines

Tight Budget Constraints – Needed to reduce development and production costs without compromising quality

No Room for Error – The robot had to perform flawlessly under real construction conditions

The Solution: End-to-End Cloud Collaboration & Simulation

GOLE leveraged a complete suite of 3DEXPERIENCE Works roles and tools, including:

- 3DEXPERIENCE SOLIDWORKS Premium

- 3D Creator & 3D Sculptor

- Simulation Designer (Structural + Motion)

- Collaborative Designer for SOLIDWORKS

- Project Planner & Social Business Analyst

- Collaborative Industry Innovator + 3DSwymer

All decisions—from design and simulation to structure and sourcing—were made on the cloud using a single platform, ensuring clear communication and real-time alignment.

Key Benefits:

CES 2024 Innovation Award – First robotic prototype recognized globally

2.5 Months to Final Design – Full development cycle achieved with speed and precision

20% Weight Reduction – Improved performance and reduced motor load

10% Lower Production Cost – Streamlined structure = smaller, cheaper components

Zero Errors in Testing – Simulation tools ensured flawless results before physical build

Use Case Highlights:

Robot Design in the Cloud – All teams co-developed on a single unified platform

Cost Control from Day One – Early decisions led to cost-efficient production

Digital Revision Management – Controlled design iterations with full traceability

Multidisciplinary Innovation – Integrated mechanical, electrical, and software elements in harmony

BOM & Sourcing Integration – Streamlined material planning and procurement through the platform

Conclusion: Engineering Smarter, Faster, and Cheaper

GOLE Robotics used the power of SOLIDWORKS and 3DEXPERIENCE Works to compress the entire development cycle of an advanced robot into just weeks—without errors, rework, or inflated costs. By unifying their teams through cloud-based collaboration and simulation, they set a new benchmark for robotic innovation in the construction industry.