Industry: Aerospace · Energy · Automotive · Oil & Gas

Technology: Metal Additive Manufacturing (MPBF)

Machine Used: EP-M650 Metal Powder Bed Fusion System

Material: Inconel 718 (Nickel-Based Superalloy)

Overview: Superalloys Born for Extremes

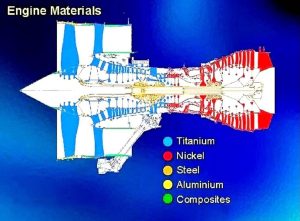

First developed in the post-WWII era, superalloys—especially those based on nickel, cobalt, or iron—have revolutionized how we engineer parts exposed to extreme heat, stress, and corrosion. Among them, Inconel 718 (IN718) stands out as a top performer in additive manufacturing, particularly in aerospace where it reportedly represents over one-third of all nickel superalloy components used in jet engines.

Its resistance to high temperatures (up to 760°C), combined with excellent mechanical strength and corrosion resistance, has made IN718 an indispensable material in:

- Aerospace (turbine blades, casings)

- Nuclear reactors (heat exchanger tubes)

- Oil & gas (downhole tools, wellhead parts)

- Defense & marine (propellers, seals, valves)

- Cryogenics (supports, casings, pumps)

Why Inconel 718 Is Ideal for 3D Printing

Traditional methods like forging, casting, and machining often limit design freedom and require costly, pre-process heat treatment—a disadvantage when working with high-performance alloys. In contrast, 3D printing Inconel 718 enables:

Complex Geometry

Designs once considered impossible to produce (internal channels, lattice structures, integrated cooling systems) are now feasible with additive manufacturing.

Superior Mechanical Properties

Printed IN718 components often meet or exceed the strength and fatigue resistance of cast/forged parts, thanks to optimized process parameters and microstructure control.

Reduced Material Waste

Unlike subtractive methods, additive manufacturing uses only the material needed, significantly reducing wastage—especially important for costly alloys like IN718.

Overcomes Machining Difficulties

IN718 is notoriously hard to machine due to severe work hardening and high cutting temperatures. 3D printing bypasses these challenges entirely.

EP-M650: Designed for Large-Scale Inconel 718 Applications

The EP-M650 metal 3D printer is purpose-built for industrial-scale production of Inconel 718 and other high-performance alloys. It uses Metal Powder Bed Fusion (MPBF) technology and features:

- Build Volume: 655 × 655 × 800 mm³

- 4-Laser System: Ensures uniform heat distribution and high throughput

- Precision Control: Stable scanning strategy and accurate layer-by-layer construction

- Material Versatility: Compatible with nickel alloys, titanium, aluminum, stainless steel, CoCr, and more

The system enables direct production of large, high-precision parts with exceptional mechanical properties, ideal for aerospace turbines, automotive components, defense equipment, and energy systems.

Featured Application:

EP-M650 successfully printed a complex aeroengine casing in IN718, showcasing the machine’s capacity for high-volume, high-value parts under demanding requirements.

Performance Range: From Cryogenics to Combustion

IN718 printed parts deliver reliable performance across a broad temperature spectrum—from cryogenic levels (-273°C) to heat-intensive applications (up to 760°C). This makes it a trusted material for:

- Cryogenic storage and support systems

- Heat exchangers and cooling tubes

- Structural impellers, valve stems, pump housings

- Combustion chambers and thermal insulation components

Conclusion: The Future of High-Temperature Part Production

Inconel 718, when paired with advanced 3D printing platforms like the EP-M650, is redefining what’s possible in modern manufacturing. Whether it’s a flight-critical turbine blade or a high-pressure downhole component, this material-machine combination delivers performance, reliability, and design freedom in one integrated solution.